22. Patent for useful model №157057

Date of registration in the state register:Compressor shaft sealing device

Patent for useful model №157057(1 MB)

Patent for useful model №157057(1 MB)

22. Patent for useful model №157057

Date of registration in the state register:Compressor shaft sealing device

Patent for useful model №157057(1 MB)

Patent for useful model №157057(1 MB)

Description

The utility model relates to the sealing technique and can be used to supply barrier gas during sealing of rotating shafts in the structures of centrifugal compressors, in particular, in sealing systems of gas pumping units.

The technical result of the proposed utility model is to increase the safety of the compressor shaft seals at elevated loads of equipment operation in the following modes: compressor start-up, stabilization, shutdown and emergency shutdown, as well as reducing the cost of servicing the Gas Pumping Unit (GPU) by simplifying the already existing structures and using combined supply schemes of barrier gas.

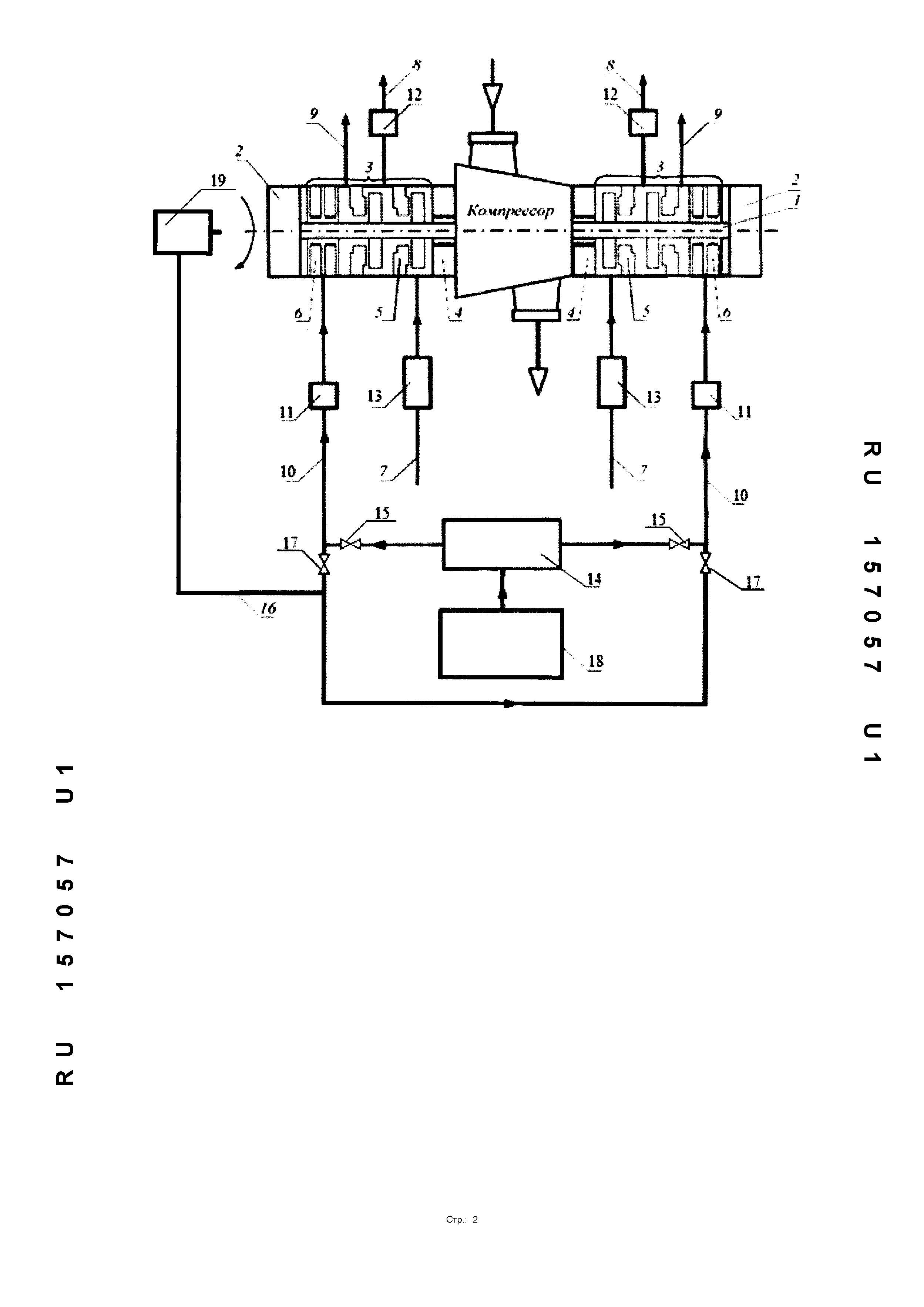

This technical result is achieved in a compressor shaft sealing device, comprising a compressor shaft with bearings and end seals installed at its ends, each of which includes sequentially located from the compressor impeller to the labyrinth seal bearings, a gas dynamic seals assembly and a barrier seals assembly, in between there are chambers between the seals, a gas supply line to the chamber located between the labyrinth seals and hub end gas seals, gas supply line to the barrier seal assembly; leakage line from the gas-end seals assembly; and leakage line from the chamber located between the gas-dynamic seal end assembly and barrier seals assembly; the gas supply line to the barrier seal assemblies is connected to a gas source that does not form an explosive mixture with process gas, the leakage lines from the chambers located between the nodes of the gas-dynamic face seals and the barrier seal assemblies have access to the atmosphere, and the leakage lines gas seals of the end nodes also have access to the atmosphere and provided with leakage control nodes, and as the gas source, not forming an explosive mixture with process gas, a plant for producing nitrogen, ACCORDING TO THE USEFUL MODEL, the gas supply line to the barrier seal assemblies is connected to the gas source through the receiver and is equipped with a gas supply valve, and through the air supply valve it is connected to the barrier air supply line from the engine compressor.